ARTICLE

The general classification and principle of UV light

2021-10-05

Today, I will introduce you to the general classification and principle of UV light. Usually, our catchy ultraviolet light or UV light,

It is often explained by a general term, but in fact, there is a general classification in the definition of UV light.

In terms of the common definition of UV, because it is called the purple "outer line", the light that is invisible to our human eyes is called the "outer line".

Therefore, the marking range of visible light is usually 380nm as the limit, so we say that the starting point of UV light is 380nm.

In the conventional UV light classification, we divide it into 3 categories:

In these three types of ultraviolet light, each will appear in a different field, although the classification is so fine.

But in fact, we will be exposed to UVA and a very small amount of UVB in nature at most, so why can't we get in touch with UVC?

Because UVC decomposes oxygen to produce ozone, it is usually absorbed in the atmosphere, so our earth’s atmosphere is full of a thick layer of ozone.

Therefore, it is difficult for UVC light to directly reach the surface of the earth so that we can be exposed. Unless a hole is found in the ozone layer as observed by scientists, there is a chance that UVC light can reach the earth's surface directly.

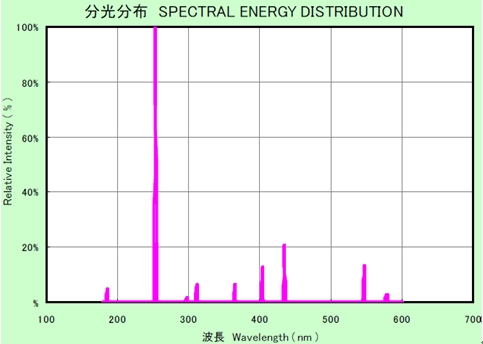

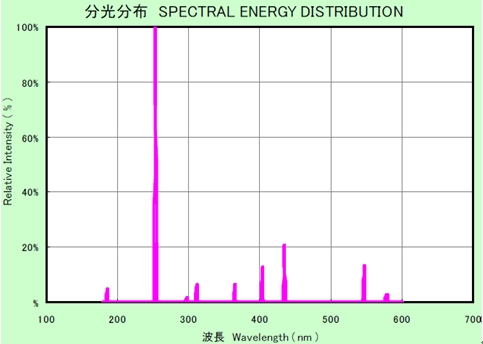

Therefore, we often talk about the sources of UVC light sources, almost all come from artificial light sources, and mercury lamps are the most mature source of UVC artificial light sources. Figure 1 below is the most common UVC spectrum.

As for the UVB part, because it is between UVA and UVC, it’s a little less will be explained separately.

However, UVB still has its importance in the field of photocuring. Let's take the spectrum reflected by the photoinitiator in Figure 2 below.

In the part of UVB, there are still many photoinitiators involved in its reflection, so if UV materials are to achieve a complete reaction, UVB is still necessary

The source of the artificial light source of UVB is also the most common source of mercury lamps. Whether it is a standard mercury lamp or a doped mercury lamp, UVB has its own proportion.

For example, in standard mercury lamps, UVB accounts for about 30% of the proportion, while in doped mercury lamps, it is about 10-20%.

.jpg)

Figure 2: The proportion and importance of UVB in the photoinitiator.

Next, let’s talk about the part of UVA. UVA is our most common source of UV light and it is the most versatile.

Because of the wide range of uses of UVA, doped mercury lamps have also been produced. Because doped mercury lamps account for about 80% of the light-emitting spectrum, UVA accounts for about 80%.

It takes the light that should have been generated in UVC and UVB because of the change in wavelength shift due to metal doping, and makes the wavelength of UVA the main spectral distribution.

Therefore, doped mercury lamps are one of the most commonly used light sources in industrial UV curing applications.

Figure 3 shows the difference in the spectral distribution of a standard mercury lamp (left) and a doped mercury lamp (right). It can be clearly found that the entire wavelength has changed from an even distribution to a UVA part.

.jpg)

Figure 3. The difference in spectral distribution between a standard mercury lamp (left) and a doped mercury lamp (right)

In general, after we get the UV materials, in addition to referring to the technical information provided by the original factory, we must also understand whether our own application is consistent with the technical information provided by the original factory.

And whether the type of own UV light source is suitable for the application of UV materials, these are the key points for considering whether a good curing can be achieved.

Truster Industrial adheres to the principle of "Light Experts" with our focus on solving your problems.

Continuously assist customers in verifying the best curing conditions for test materials. The dedicated "light laboratory" is equipped with a variety of common UV light sources on the market.

Provide customers with the most detailed and best choices.

►Truster UV LED products

https://truster.com.tw/en/product/1518016414

Back

It is often explained by a general term, but in fact, there is a general classification in the definition of UV light.

In terms of the common definition of UV, because it is called the purple "outer line", the light that is invisible to our human eyes is called the "outer line".

Therefore, the marking range of visible light is usually 380nm as the limit, so we say that the starting point of UV light is 380nm.

In the conventional UV light classification, we divide it into 3 categories:

- ►Short-wave ultraviolet (UV-C), the wavelength is 200--280nm

- ►Medium-wave ultraviolet (UV-B), the wavelength is 280-320nm

- ►Long wave ultraviolet (UV-A), the wavelength is 320--380nm

In these three types of ultraviolet light, each will appear in a different field, although the classification is so fine.

But in fact, we will be exposed to UVA and a very small amount of UVB in nature at most, so why can't we get in touch with UVC?

Because UVC decomposes oxygen to produce ozone, it is usually absorbed in the atmosphere, so our earth’s atmosphere is full of a thick layer of ozone.

Therefore, it is difficult for UVC light to directly reach the surface of the earth so that we can be exposed. Unless a hole is found in the ozone layer as observed by scientists, there is a chance that UVC light can reach the earth's surface directly.

Therefore, we often talk about the sources of UVC light sources, almost all come from artificial light sources, and mercury lamps are the most mature source of UVC artificial light sources. Figure 1 below is the most common UVC spectrum.

Figure 1: UVC spectral distribution of mercury lamp

Figure 1: UVC spectral distribution of mercury lampFigure 1: UVC spectral distribution of mercury lamp

As for the UVB part, because it is between UVA and UVC, it’s a little less will be explained separately.

However, UVB still has its importance in the field of photocuring. Let's take the spectrum reflected by the photoinitiator in Figure 2 below.

In the part of UVB, there are still many photoinitiators involved in its reflection, so if UV materials are to achieve a complete reaction, UVB is still necessary

The source of the artificial light source of UVB is also the most common source of mercury lamps. Whether it is a standard mercury lamp or a doped mercury lamp, UVB has its own proportion.

For example, in standard mercury lamps, UVB accounts for about 30% of the proportion, while in doped mercury lamps, it is about 10-20%.

.jpg)

Figure 2: The proportion and importance of UVB in the photoinitiator.

Next, let’s talk about the part of UVA. UVA is our most common source of UV light and it is the most versatile.

Because of the wide range of uses of UVA, doped mercury lamps have also been produced. Because doped mercury lamps account for about 80% of the light-emitting spectrum, UVA accounts for about 80%.

It takes the light that should have been generated in UVC and UVB because of the change in wavelength shift due to metal doping, and makes the wavelength of UVA the main spectral distribution.

Therefore, doped mercury lamps are one of the most commonly used light sources in industrial UV curing applications.

Figure 3 shows the difference in the spectral distribution of a standard mercury lamp (left) and a doped mercury lamp (right). It can be clearly found that the entire wavelength has changed from an even distribution to a UVA part.

.jpg)

Figure 3. The difference in spectral distribution between a standard mercury lamp (left) and a doped mercury lamp (right)

In general, after we get the UV materials, in addition to referring to the technical information provided by the original factory, we must also understand whether our own application is consistent with the technical information provided by the original factory.

And whether the type of own UV light source is suitable for the application of UV materials, these are the key points for considering whether a good curing can be achieved.

Truster Industrial adheres to the principle of "Light Experts" with our focus on solving your problems.

Continuously assist customers in verifying the best curing conditions for test materials. The dedicated "light laboratory" is equipped with a variety of common UV light sources on the market.

Provide customers with the most detailed and best choices.

►Truster UV LED products

https://truster.com.tw/en/product/1518016414